-

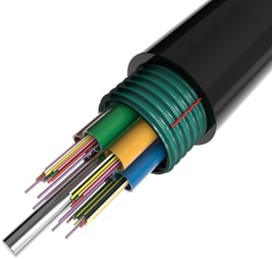

Fiber Optic Cable Aerial 9/125 outdoor multi tube

Technical characteristics

1) The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

2) The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties Multiple water blocking material filling provides dual water blocking function

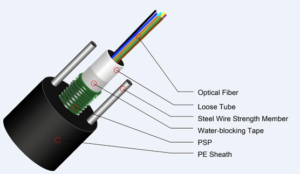

Construction:

- Fiber single mode G652D

- Gel core filling

- Center strength member FRP

- Multi Loose tube

- Fastening winding of threads and tapes.

- 0MM*7pcs Stranded galvanize messenger wire

- MDPE sheath

Fiber count

12

24

48

96No of loose tube/filler

2/3

4/1

6

8Fiber No. per tube

6

6

8

12Loose tube diameter

1.6±0.1mmCenter strength member

Steel wire 1.6±0.1mmOuter sheath thickness

1.5±0.1mmMessenger wire

1.0MM*7pcs galvanized steelWater proof type

Gel filledOuter sheath material

MDPECable OD mm

8.0*15.0MM±0.2mmCable weight

110KG/KMTensile

4KNOperation temperature range

-40 ℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature range

-40 ℃ to + 70 ℃Crush resistance

1000 N/10cmMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

Fiber Optic Cable Aerial 9/125 outdoor Multi-tube

Fiber count

2

4

6

8

12Max. No of loose tube

1Fiber No. per tube

2

4

6

8

12Loose tube diameter

2.0±0.1mmOuter sheath thickness

1.6±0.1mmMessenger wire

1.0MM*7pcs galvanized steelOuter sheath material

HDPECable OD mm

10.6-11MM *5.0-5.2MMCable weight

66KG/KMTensile

3KNOperation temperature range

-40 d℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

-40 ℃ to + 70 ℃Crush resistance

1000 N/10cmMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

Fiber Optic Cable Aerial 9/125 outdoor Uni-tube

Fiber count

2

4

6

8

12Max. No of loose tube

1Fiber No. per tube

2

4

6

8

12Loose tube diameter

2.0±0.1mmOuter sheath thickness

1.6±0.1mmMessenger wire

1.0MM*7pcs galvanized steelOuter sheath material

HDPECable OD mm

10.6-11MM *5.0-5.2MMCable weight

66KG/KMTensile

3KNOperation temperature range

-40 d℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

-40 ℃ to + 70 ℃Crush resistance

1000 N/10cmMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

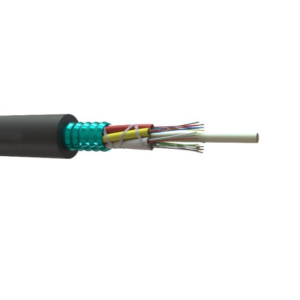

Fiber Optic Cable Armoured 9/125 outdoor multi tube

Technical characteristics

1) The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

2) The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties Multiple water blocking material filling provides dual water blocking function

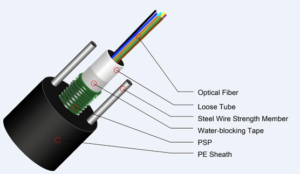

Construction:

- Fiber single mode G652D

- Gel core filling

- Center strength member steel wire

- Multi Loose tube

- Corrugated steel armor

- Cable jelly

- Red rip cord

- PE sheath

Fiber count

24Max. No of loose tube/ filler

4/1Fiber No. per tube

6Center strength member

Steel wire 1.4±0.1MMLoose tube diameter

1.7±0.1mmArmored

Corrugated steelWater proof type

Gel filledOuter sheath thickness

1.5±0.1mmOuter sheath material

HDPECable OD mm

8.8±0.2MMCable weight

82KG±5/KMTensile

4KNOperation temperature range

-40 d℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

-40 ℃ to + 70 ℃Crush resistance

1000 N/10cmMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

Fiber Optic Cable Armoured 9125 outdoor Multi-tube

Optics Specifications

Attenuation(dB/km)

@1310nm

≤0.34db/km@1383nm (after hydrogen aging)

≤0.32db/km@1550nm

≤0.20db/km@1625nm

≤0.24db/kmDispersion

@1285nm~1340nm

-3.0~3.0ps/(nm*km)@1550nm

≤18ps/(nm*km)@1625nm

≤22ps/(nm*km)Zero-Dispersion wavelength

1300~1324nmZero-Dispersion slope

≤0.092ps/(nm2*km)Mode field diameter @ 1310nm

9.2±0.4μmMode field diameter @ 1550nm

10.4±0.8μmPMD

Max. value for fiber on the reel

0.2ps/km 1/2Max. Designed value for link

0.08ps/km 1/2Cable cutoff wavelength,λ cc

≤1260nmEffective group index(Neff)@1310nm

1.4675Effective group index(Neff)@1550nm

1.4680Macro-bend loss(Φ60mm,100 turns)@1550nm

≤0.05dbBack scatter characteristic(@1310nm&1550nm)

Point discontinuity

≤0.05dbAttenuation uniformity

≤0.05db/kmAttenuation coefficient difference for bi-directional measurement

≤0.05db/kmGeometrical characteristics

Cladding diameter

125±1μmCladding non-circularity

≤1%Core/cladding concentricity error

≤0.4μmFiber diameter with coating(uncolored)

245±5μmCladding/coating concentricity error

≤12.0μmCurl

≥4mMechanical characteristic

Proof test

0.69GPaCoating strip force(typical value)

1.4NDynamic stress corrosion susceptibility parameter(typical value)

≥20Environmental characteristics(@1310nm&1550nm)

Temperature induced attenuation(-60~+85℃)

≤0.5dB/kmDry heat induced attenuation(85±2℃,30days)

≤0.5dB/kmWater immersion induced attenuation(23±2℃,30days)

≤0.5dB/kmDamp heat induced attenuation(85±2℃,RH85%,30days)

≤0.5dB/km

Fiber count

2

4

6

8

12Fiber No. per tube

2

4

6

8

12Loose tube diameter/Material

2.2+0.2mm/PBTOuter sheath thickness &Material

1.5-1.8mm HDPEStrength member

Steel tape +Two steel wireCable overall diameter

8.5±0.2mmCable weight

Approx 65 kg/kmOperation temperature range

-40 ℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

– 40 ℃ to + 70 ℃Allowable Tensile Load(N)

2000NCrush resistance

Short term :2200N/100MM Long term:1100N/100MM

Minimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

Fiber Optic Cable Armoured 9125 outdoor Uni-tube

Optics Specifications

Attenuation(dB/km)

@1310nm

≤0.34db/km@1383nm (after hydrogen aging)

≤0.32db/km@1550nm

≤0.20db/km@1625nm

≤0.24db/kmDispersion

@1285nm~1340nm

-3.0~3.0ps/(nm*km)@1550nm

≤18ps/(nm*km)@1625nm

≤22ps/(nm*km)Zero-Dispersion wavelength

1300~1324nmZero-Dispersion slope

≤0.092ps/(nm2*km)Mode field diameter @ 1310nm

9.2±0.4μmMode field diameter @ 1550nm

10.4±0.8μmPMD

Max. value for fiber on the reel

0.2ps/km 1/2Max. Designed value for link

0.08ps/km 1/2Cable cutoff wavelength,λ cc

≤1260nmEffective group index(Neff)@1310nm

1.4675Effective group index(Neff)@1550nm

1.4680Macro-bend loss(Φ60mm,100 turns)@1550nm

≤0.05dbBack scatter characteristic(@1310nm&1550nm)

Point discontinuity

≤0.05dbAttenuation uniformity

≤0.05db/kmAttenuation coefficient difference for bi-directional measurement

≤0.05db/kmGeometrical characteristics

Cladding diameter

125±1μmCladding non-circularity

≤1%Core/cladding concentricity error

≤0.4μmFiber diameter with coating(uncolored)

245±5μmCladding/coating concentricity error

≤12.0μmCurl

≥4mMechanical characteristic

Proof test

0.69GPaCoating strip force(typical value)

1.4NDynamic stress corrosion susceptibility parameter(typical value)

≥20Environmental characteristics(@1310nm&1550nm)

Temperature induced attenuation(-60~+85℃)

≤0.5dB/kmDry heat induced attenuation(85±2℃,30days)

≤0.5dB/kmWater immersion induced attenuation(23±2℃,30days)

≤0.5dB/kmDamp heat induced attenuation(85±2℃,RH85%,30days)

≤0.5dB/km

Fiber count

2

4

6

8

12Fiber No. per tube

2

4

6

8

12Loose tube diameter/Material

2.2+0.2mm/PBTOuter sheath thickness &Material

1.5-1.8mm HDPEStrength member

Steel tape +Two steel wireCable overall diameter

8.5±0.2mmCable weight

Approx 65 kg/kmOperation temperature range

-40 ℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

– 40 ℃ to + 70 ℃Allowable Tensile Load(N)

2000NCrush resistance

Short term :2200N/100MM Long term:1100N/100MM

Minimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

Fiber Optic Cable SM 9125 outdoor

Fiber count

2-8

12Fiber type

Single Mode G652DMax. No of loose tube

1Fiber No. per tube

2-8

12Loose tube diameter

1.6mm

2.0mmOuter sheath thickness

1.5mmFRP Strength member

0.8mm

1.0mmOuter sheath

HDPECable OD mm

4.6±0.2mm

5.8±0.2mmCable weight kg/km

19

30Operation temperature range

-40 d℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature range

-40 ℃ to + 70 ℃Allowable Tensile Load(N)

Short term:1500 Long term:600Crush resistance

1000 N/10cm 2200N/10CMMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x OD -

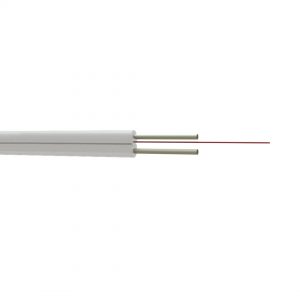

Fiber Optic DROP Cable FO1 Aerial outdoor G657A2

Fiber count: 1/2/4

Color of fiber: Blue, Orange, Green, Brown, Grey

Fiber Type: G657A2

Strength member: Steel wire/FRP

Supporting messenger wire: 1.0MM*x1 steel wire

Outer sheath: LSZH Lower smoke zero halogen frame retardant & UV Anti

Cable Diameter dimensions: 2.0( Height) × 5.0W ± 0.1 mm(width)

Operation temperature range: -20 ℃ to + 70 ℃

Installation temperature range: -20 ℃ to + 60 ℃

Transport and storage temperature range: -20 ℃ to + 70 ℃

Tension Load (N): Short term :800N Long term :500N

Crush Load(N): Long term 1000 N/100mm Short term:2200N/100mm

Minimal installation bending radius: 30 x OD

Minimal operation bending radius: 15 x OD

Cable marking: The marking length 1meter apart , as requiredCategory

Description

G657A1

G657A2/B2Standard

StandardOptical transmission performance

Attenuation coefficient

1310nm

≤0.35

≤0.351383nm

≤0.35

≤0.351550nm

≤0.21

≤0.211625nm

≤0.23

≤0.23Attenuation inhomogeneity

1310nm、1550nm

≤0.03

≤0.05Attenuation discontinuity

1310nm、1550nm

≤0.03

≤0.05Wavelength attenuation

characteristics

1288~1330nm

≤0.05

≤0.051525~1575nm

≤0.05

≤0.05Dispersion characteristic

The zero dispersion wavelengthnm

1300~1324

1300~1324Zero dispersion slope

≤0.092

≤0.0921288~1339nm

≤3.5

≤3.51271~1360nm

≤5.3

≤5.31550nm

≤18

≤181625nm

≤22

≤22The polarization mode dispersion of the fiber

≤0.1

≤0.1Fiber cutoff wavelength

≤1260

≤1260Macro bending loss

(10 laps,30mm)

1550nm

≤0.2dB

≤0.03(10 laps,30mm)

1625nm

≤0.5dB

≤0.1(1 lap,20mm)

1550nm

≤0.3dB

≤0.1(1 lap,20mm)

1625nm

≤1.0dB

≤0.2(1 lap,15mm)

1550nm

–

≤0.5(1 lap,15mm)

1625nm

–

≤1.0Mode field diameter

1310nm

8.8±0.4

8.6±0.4Dimension parameter

Warp degrees

≥4.0

≥4.0Cladding diameter

125 ± 0.7

125 ± 0.7Core/package concentricity

≤0.5

≤0.5Cladding non-circularity

≤1.0%

≤1.0%Coating diameter

243± 5

243± 5Coating concentricity

≤8

≤8Coating roundness

≤3%

≤3%Mechanical property

Strain

≥1.05%

≥1.05%Tensile strength(10m)

15% Weber fracture probability

2.76

2.76

50% Weber fracture probability

3.45

3.45Fatigue parameters Nd

≥ 22

≥ 22Coating peak stripping force N

1.0~8.9

1.0~8.9Coating average stripping force N

1.0~5.0

1.0~5.0Environmental performance

Additional damping temperature cycle (-60℃ ~ +85℃)dB/km@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm,

≤ 0.05

≤ 0.05

1550nm, 1625 nm

High temperature aging(85±2℃,30 days ) dB/km @1310nm,1550

nm, 1625 nm

≤ 0.05

≤ 0.05Additional attenuation of flooding (23±2℃,30 days ) dB/km

@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05 -

Fiber Optic DROP Cable FO1 SM indoor G657A2

The typical bow-type drop optical cable includes central optical fibers with 2 Steel wire as the strength members placed on both sides, a LSZH sheath is extruded outside.

Fiber Optical

Fiber count

1/2Color Of fiber

Blue OrangeFiber Type

G657A2Strength member

Galvanized steel wireOuter sheath

LSZH(white)Cable Diameter dimensions

2.0( Height) × 3.0W ± 0.1 mm(width)Operation temperature range

-20 ℃ to + 70 ℃Installation temperature range

-0 ℃ to + 60 ℃Transport and storage temperature range

-20 ℃ to + 70 ℃Minimal installation bending radius

30 x ODMinimal operation bending radius

15 x ODCable marking

The marking length 1meter apart , as requiredG657A2 fiber

Category

Description

G657A1

G657A2/B2Standard

StandardOptical transmission performance

Attenuation coefficient

1310nm

≤0.35

≤0.351383nm

≤0.35

≤0.351550nm

≤0.21

≤0.211625nm

≤0.23

≤0.23Attenuation inhomogeneity

1310nm、1550nm

≤0.03

≤0.05Attenuation discontinuity

1310nm、1550nm

≤0.03

≤0.05Wavelength attenuation

characteristics

1288~1330nm

≤0.05

≤0.051525~1575nm

≤0.05

≤0.05Dispersion characteristic

The zero dispersion wavelengthnm

1300~1324

1300~1324Zero dispersion slope

≤0.092

≤0.0921288~1339nm

≤3.5

≤3.51271~1360nm

≤5.3

≤5.31550nm

≤18

≤181625nm

≤22

≤22The polarization mode dispersion of the fiber

≤0.1

≤0.1Fiber cutoff wavelength

≤1260

≤1260Macro bending loss

(10 laps,30mm)

1550nm

≤0.2dB

≤0.03(10 laps,30mm)

1625nm

≤0.5dB

≤0.1(1 lap,20mm)

1550nm

≤0.3dB

≤0.1(1 lap,20mm)

1625nm

≤1.0dB

≤0.2(1 lap,15mm)

1550nm

–

≤0.5(1 lap,15mm)

1625nm

–

≤1.0Mode field diameter

1310nm

8.8±0.4

8.6±0.4Dimension parameter

Warp degrees≥4.0

≥4.0Cladding diameter

125 ± 0.7

125 ± 0.7Core/package concentricity

≤0.5

≤0.5Cladding non-circularity

≤1.0%

≤1.0%Coating diameter

243± 5

243± 5Coating concentricity

≤8

≤8Coating roundness

≤3%

≤3%Mechanical property

Strain≥1.05%

≥1.05%Tensile strength(10m)

15% Weber fracture probability

2.76

2.7650% Weber fracture probability

3.45

3.45Fatigue parameters Nd

≥ 22

≥ 22Coating peak stripping force N

1.0~8.9

1.0~8.9Coating average stripping force N

1.0~5.0

1.0~5.0Environmental

performance

Additional damping temperature cycle (-60℃ ~ +85℃)dB/km@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm,

1550nm, 1625 nm

≤ 0.05

≤ 0.05High temperature aging(85±2℃,30 days ) dB/km @1310nm,1550

nm, 1625 nm

≤ 0.05

≤ 0.05Additional attenuation of flooding (23±2℃,30 days ) dB/km

@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05 -

Fiber Optic DROP Cable FO2 SM indoor G657A2

The typical bow-type drop optical cable includes central optical fibers with 2 Steel wire as the strength members placed on both sides, a LSZH sheath is extruded outside.

Fiber Optical

Fiber count

1/2Color Of fiber

Blue OrangeFiber Type

G657A2Strength member

Galvanized steel wireOuter sheath

LSZH(white)Cable Diameter dimensions

2.0( Height) × 3.0W ± 0.1 mm(width)Operation temperature range

-20 ℃ to + 70 ℃Installation temperature range

-0 ℃ to + 60 ℃Transport and storage temperature range

-20 ℃ to + 70 ℃Minimal installation bending radius

30 x ODMinimal operation bending radius

15 x ODCable marking

The marking length 1meter apart , as requiredG657A2 fiber

Category

Description

G657A2/B2Optical

transmission

performance

Attenuation coefficient

1310nm

≤0.351383nm

≤0.351550nm

≤0.211625nm

≤0.23Attenuation inhomogeneity

1310nm, 1550nm

≤0.05Attenuation discontinuity

1310nm, 1550nm

≤0.05Wavelength attenuation

characteristics

1228 ~ 1330nm

≤0.051525 ~ 1575nm

≤0.05Dispersion characteristic

The zero dispersion wavelength nm

1300~1324Zero dispersion slope

≤0.0921288~1339nm

≤3.51271~1360nm

≤5.31550nm

≤181625nm

≤22The polarization mode dispersion of the fiber

≤0.1Fiber cutoff wavelength

≤1260Macro bending loss

(10 laps,30mm)

1550nm

≤0.03(10 laps,30mm)

1625nm

≤0.1(1 lap,20mm)

1550nm

≤0.1(1 lap,20mm)

1625nm

≤0.2(1 lap,15mm)

1550nm

≤0.5(1 lap,15mm)

1625nm

≤1.0Mode field diameter

1310nm

8.6±0.4Dimension

parameter

Warp degrees≥4.0

Cladding diameter

125 ± 0.7

Core/package concentricity

≤0.5

Cladding non-circularity

≤1.0%

Coating diameter

243± 5

Coating concentricity

≤8

Coating roundness

≤3%

Mechanical

property

Strain≥1.05%

Tensile strength(10m)

15% Weber fracture probability

2.7650% Weber fracture probability

3.45Fatigue parameters Nd

≥ 22

Coating peak stripping force N

1.0~8.9

Coating average stripping force N

1.0~5.0

Environmental

performance

Additional damping temperature cycle (-60℃ ~ +85℃)

dB/km@1310nm,1550nm, 1625 nm

≤ 0.05Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm, 1550nm, 1625 nm

≤ 0.05High temperature aging(85±2℃,30 days ) dB/km @1310nm, 1550nm, 1625 nm

≤ 0.05Additional attenuation of flooding (23±2℃,30 days ) dB/km

@1310nm,1550nm, 1625 nm

≤ 0.05 -

Fiber Optic DROP Cable FO4 Aerial outdoor G657A

Fiber count

1/2/4Color Of fiber

Blue Orange Green Brown GreyFiber Type

G657A2Strength member

Steel wire/FRPSupporting messenger wire

1.0MM*x1 steel wireOuter sheath

LSZH Lower smoke zero halogen frame retardant & UV AntiCable Diameter dimensions

2.0( Height) × 5.0W ± 0.1 mm(width)Operation temperature range

-20 ℃ to + 70 ℃Installation temperature range

-20 ℃ to + 60 ℃Transport and storage temperature range

-20 ℃ to + 70 ℃Tension Load (N)

Short term :800N Long term :500NCrush Load(N)

Long term 1000 N/100mm Short term:2200N/100mmMinimal installation bending radius

30 x ODMinimal operation bending radius

15 x ODCable marking

The marking length 1meter apart , as requiredCategory

Description

G657A1

G657A2/B2Standard

StandardOptical transmission performance

Attenuation coefficient

1310nm

≤0.35

≤0.351383nm

≤0.35

≤0.351550nm

≤0.21

≤0.211625nm

≤0.23

≤0.23Attenuation inhomogeneity

1310nm、1550nm

≤0.03

≤0.05Attenuation discontinuity

1310nm、1550nm

≤0.03

≤0.05Wavelength attenuation

characteristics

1288~1330nm

≤0.05

≤0.051525~1575nm

≤0.05

≤0.05Dispersion characteristic

The zero dispersion wavelengthnm

1300~1324

1300~1324Zero dispersion slope

≤0.092

≤0.0921288~1339nm

≤3.5

≤3.51271~1360nm

≤5.3

≤5.31550nm

≤18

≤181625nm

≤22

≤22The polarization mode dispersion of the fiber

≤0.1

≤0.1Fiber cutoff wavelength

≤1260

≤1260Macro bending loss

(10 laps,30mm)

1550nm

≤0.2dB

≤0.03(10 laps,30mm)

1625nm

≤0.5dB

≤0.1(1 lap,20mm)

1550nm

≤0.3dB

≤0.1(1 lap,20mm)

1625nm

≤1.0dB

≤0.2(1 lap,15mm)

1550nm

–

≤0.5(1 lap,15mm)

1625nm

–

≤1.0Mode field diameter

1310nm

8.8±0.4

8.6±0.4Dimension parameter

Warp degrees

≥4.0

≥4.0Cladding diameter

125 ± 0.7

125 ± 0.7Core/package concentricity

≤0.5

≤0.5Cladding non-circularity

≤1.0%

≤1.0%Coating diameter

243± 5

243± 5Coating concentricity

≤8

≤8Coating roundness

≤3%

≤3%Mechanical property

Strain

≥1.05%

≥1.05%Tensile strength(10m)

15% Weber fracture probability

2.76

2.76

50% Weber fracture probability

3.45

3.45Fatigue parameters Nd

≥ 22

≥ 22Coating peak stripping force N

1.0~8.9

1.0~8.9Coating average stripping force N

1.0~5.0

1.0~5.0Environmental performance

Additional damping temperature cycle (-60℃ ~ +85℃)dB/km@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm,

≤ 0.05

≤ 0.05

1550nm, 1625 nm

High temperature aging(85±2℃,30 days ) dB/km @1310nm,1550

nm, 1625 nm

≤ 0.05q

≤ 0.05Additional attenuation of flooding (23±2℃,30 days ) dB/km

@1310nm,1550nm, 1625 nm

≤ 0.05

≤ 0.05 -

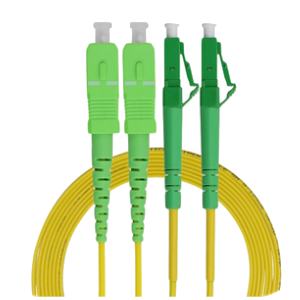

Optic Patch Cord LC-LC SM 9/125 DX

The optical fiber patch cords are suitable for data communication, telecommunication applications.

Our patch cords are with standard optical specifications, precise length tolerances.

All assemblies are 100% inspected for optical characteristics and fiber end face finish.

The terminated connectors in assemblies are designed to and are compatible with industry standardsFeatures:

- Adopts high precision ceramic ferrule with good concentricity

- Compact & strong crimping offers exceptional tensile strength in cable assemblies

- 100% inspected for optical characteristics & fiber endface finish

- Low insertion loss & return loss, clean and LCratch-free end faces

- Good performance endurance under changing circumstances

-

Optic Patch Cord SC-LC APC SM 9/125 DX

The optical fiber patch cords are suitable for data communication, telecommunication applications. Our patch cords are with standard optical specifications, precise length tolerances.

All assemblies are 100% inspected for optical characteristics and fiber end face finish.

The terminated connectors in assemblies are designed to and are compatible with industry standardsFeatures:

- Adopts high precision ceramic ferrule with good concentricity

- Compact & strong crimping offers exceptional tensile strength in cable assemblies

- 100% inspected for optical characteristics & fiber endface finish

- Low insertion loss & return loss, clean and scratch-free end faces

- Good performance endurance under changing circumstances

-

Optic Patch Cord SC-LC MM 50/125 DX OM3

The optical fiber patch cords are suitable for data communication, telecommunication applications. Our patch cords are with standard optical specifications, precise length tolerances.

All assemblies are 100% inspected for optical characteristics and fiber end face finish.

The terminated connectors in assemblies are designed to and are compatible with industry standardsFeatures:

- Adopts high precision ceramic ferrule with good concentricity

- Compact & strong crimping offers exceptional tensile strength in cable assemblies

- 100% inspected for optical characteristics & fiber endface finish

- Low insertion loss & return loss, clean and scratch-free end faces

- Good performance endurance under changing circumstances