-

Technical characteristics

1) The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

2) The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties Multiple water blocking material filling provides dual water blocking function

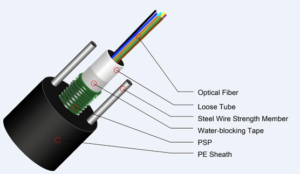

Construction:

- Fiber single mode G652D

- Gel core filling

- Center strength member steel wire

- Multi Loose tube

- Corrugated steel armor

- Cable jelly

- Red rip cord

- PE sheath

Fiber count

24Max. No of loose tube/ filler

4/1Fiber No. per tube

6Center strength member

Steel wire 1.4±0.1MMLoose tube diameter

1.7±0.1mmArmored

Corrugated steelWater proof type

Gel filledOuter sheath thickness

1.5±0.1mmOuter sheath material

HDPECable OD mm

8.8±0.2MMCable weight

82KG±5/KMTensile

4KNOperation temperature range

-40 d℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

-40 ℃ to + 70 ℃Crush resistance

1000 N/10cmMinimal installation bending radius

20 x ODMinimal operation bending radius

10 x ODFiber Optic Cable Armoured 9/125 outdoor multi tube

-

Optics Specifications

Attenuation(dB/km)

@1310nm

≤0.34db/km@1383nm (after hydrogen aging)

≤0.32db/km@1550nm

≤0.20db/km@1625nm

≤0.24db/kmDispersion

@1285nm~1340nm

-3.0~3.0ps/(nm*km)@1550nm

≤18ps/(nm*km)@1625nm

≤22ps/(nm*km)Zero-Dispersion wavelength

1300~1324nmZero-Dispersion slope

≤0.092ps/(nm2*km)Mode field diameter @ 1310nm

9.2±0.4μmMode field diameter @ 1550nm

10.4±0.8μmPMD

Max. value for fiber on the reel

0.2ps/km 1/2Max. Designed value for link

0.08ps/km 1/2Cable cutoff wavelength,λ cc

≤1260nmEffective group index(Neff)@1310nm

1.4675Effective group index(Neff)@1550nm

1.4680Macro-bend loss(Φ60mm,100 turns)@1550nm

≤0.05dbBack scatter characteristic(@1310nm&1550nm)

Point discontinuity

≤0.05dbAttenuation uniformity

≤0.05db/kmAttenuation coefficient difference for bi-directional measurement

≤0.05db/kmGeometrical characteristics

Cladding diameter

125±1μmCladding non-circularity

≤1%Core/cladding concentricity error

≤0.4μmFiber diameter with coating(uncolored)

245±5μmCladding/coating concentricity error

≤12.0μmCurl

≥4mMechanical characteristic

Proof test

0.69GPaCoating strip force(typical value)

1.4NDynamic stress corrosion susceptibility parameter(typical value)

≥20Environmental characteristics(@1310nm&1550nm)

Temperature induced attenuation(-60~+85℃)

≤0.5dB/kmDry heat induced attenuation(85±2℃,30days)

≤0.5dB/kmWater immersion induced attenuation(23±2℃,30days)

≤0.5dB/kmDamp heat induced attenuation(85±2℃,RH85%,30days)

≤0.5dB/km

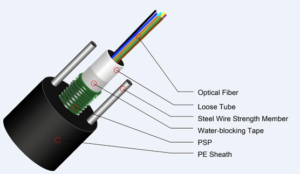

Fiber count

2

4

6

8

12Fiber No. per tube

2

4

6

8

12Loose tube diameter/Material

2.2+0.2mm/PBTOuter sheath thickness &Material

1.5-1.8mm HDPEStrength member

Steel tape +Two steel wireCable overall diameter

8.5±0.2mmCable weight

Approx 65 kg/kmOperation temperature range

-40 ℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

– 40 ℃ to + 70 ℃Allowable Tensile Load(N)

2000NCrush resistance

Short term :2200N/100MM Long term:1100N/100MM

Minimal installation bending radius

20 x ODMinimal operation bending radius

10 x ODFiber Optic Cable Armoured 9125 outdoor Multi-tube

-

Optics Specifications

Attenuation(dB/km)

@1310nm

≤0.34db/km@1383nm (after hydrogen aging)

≤0.32db/km@1550nm

≤0.20db/km@1625nm

≤0.24db/kmDispersion

@1285nm~1340nm

-3.0~3.0ps/(nm*km)@1550nm

≤18ps/(nm*km)@1625nm

≤22ps/(nm*km)Zero-Dispersion wavelength

1300~1324nmZero-Dispersion slope

≤0.092ps/(nm2*km)Mode field diameter @ 1310nm

9.2±0.4μmMode field diameter @ 1550nm

10.4±0.8μmPMD

Max. value for fiber on the reel

0.2ps/km 1/2Max. Designed value for link

0.08ps/km 1/2Cable cutoff wavelength,λ cc

≤1260nmEffective group index(Neff)@1310nm

1.4675Effective group index(Neff)@1550nm

1.4680Macro-bend loss(Φ60mm,100 turns)@1550nm

≤0.05dbBack scatter characteristic(@1310nm&1550nm)

Point discontinuity

≤0.05dbAttenuation uniformity

≤0.05db/kmAttenuation coefficient difference for bi-directional measurement

≤0.05db/kmGeometrical characteristics

Cladding diameter

125±1μmCladding non-circularity

≤1%Core/cladding concentricity error

≤0.4μmFiber diameter with coating(uncolored)

245±5μmCladding/coating concentricity error

≤12.0μmCurl

≥4mMechanical characteristic

Proof test

0.69GPaCoating strip force(typical value)

1.4NDynamic stress corrosion susceptibility parameter(typical value)

≥20Environmental characteristics(@1310nm&1550nm)

Temperature induced attenuation(-60~+85℃)

≤0.5dB/kmDry heat induced attenuation(85±2℃,30days)

≤0.5dB/kmWater immersion induced attenuation(23±2℃,30days)

≤0.5dB/kmDamp heat induced attenuation(85±2℃,RH85%,30days)

≤0.5dB/km

Fiber count

2

4

6

8

12Fiber No. per tube

2

4

6

8

12Loose tube diameter/Material

2.2+0.2mm/PBTOuter sheath thickness &Material

1.5-1.8mm HDPEStrength member

Steel tape +Two steel wireCable overall diameter

8.5±0.2mmCable weight

Approx 65 kg/kmOperation temperature range

-40 ℃ to + 70 ℃Installation temperature range

-40 ℃ to + 70 ℃Transport and storage temperature

range

– 40 ℃ to + 70 ℃Allowable Tensile Load(N)

2000NCrush resistance

Short term :2200N/100MM Long term:1100N/100MM

Minimal installation bending radius

20 x ODMinimal operation bending radius

10 x ODFiber Optic Cable Armoured 9125 outdoor Uni-tube