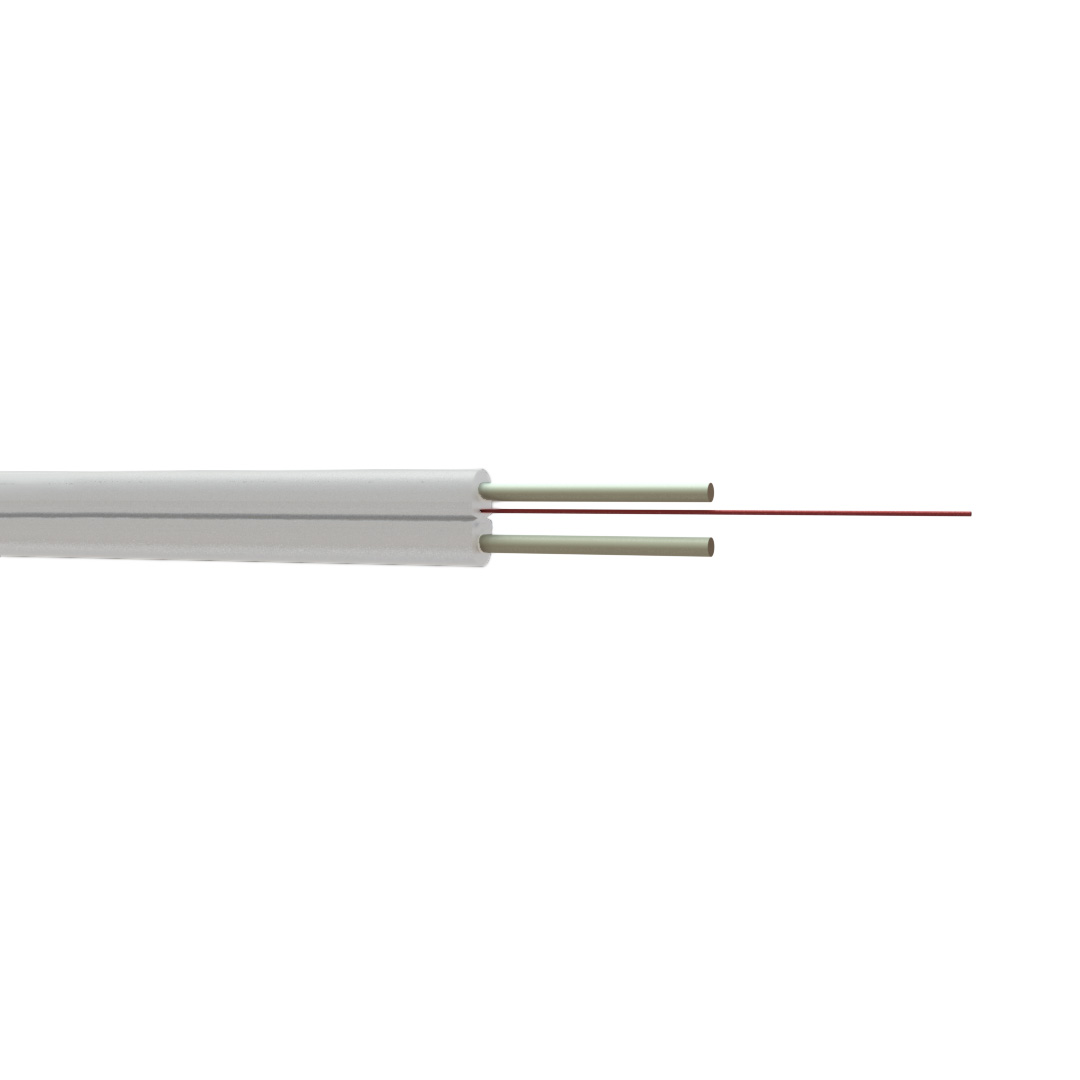

Fiber Optic DROP Cable FO1 SM indoor G657A2

The typical bow-type drop optical cable includes central optical fibers with 2 Steel wire as the strength members placed on both sides, a LSZH sheath is extruded outside.

Fiber Optical

| Fiber count | 1/2 |

| Color Of fiber | Blue Orange |

| Fiber Type | G657A2 |

| Strength member | Galvanized steel wire |

| Outer sheath | LSZH(white) |

| Cable Diameter dimensions | 2.0( Height) × 3.0W ± 0.1 mm(width) |

| Operation temperature range | -20 ℃ to + 70 ℃ |

| Installation temperature range | -0 ℃ to + 60 ℃ |

| Transport and storage temperature range | -20 ℃ to + 70 ℃ |

| Minimal installation bending radius | 30 x OD |

| Minimal operation bending radius | 15 x OD |

| Cable marking | The marking length 1meter apart , as required |

G657A2 fiber

| Category | Description | G657A1 | G657A2/B2 | |

| Standard | Standard | |||

| Optical transmission performance | Attenuation coefficient | 1310nm | ≤0.35 | ≤0.35 |

| 1383nm | ≤0.35 | ≤0.35 | ||

| 1550nm | ≤0.21 | ≤0.21 | ||

| 1625nm | ≤0.23 | ≤0.23 | ||

| Attenuation inhomogeneity | 1310nm、1550nm | ≤0.03 | ≤0.05 | |

| Attenuation discontinuity | 1310nm、1550nm | ≤0.03 | ≤0.05 | |

| Wavelength attenuation

characteristics |

1288~1330nm | ≤0.05 | ≤0.05 | |

| 1525~1575nm | ≤0.05 | ≤0.05 | ||

| Dispersion characteristic | The zero dispersion wavelength

nm |

1300~1324 | 1300~1324 | |

| Zero dispersion slope | ≤0.092 | ≤0.092 | ||

| 1288~1339nm | ≤3.5 | ≤3.5 | ||

| 1271~1360nm | ≤5.3 | ≤5.3 | ||

| 1550nm | ≤18 | ≤18 | ||

| 1625nm | ≤22 | ≤22 | ||

| The polarization mode dispersion of the fiber | ≤0.1 | ≤0.1 | ||

| Fiber cutoff wavelength | ≤1260 | ≤1260 | ||

| Macro bending loss

(10 laps,30mm) |

1550nm | ≤0.2dB | ≤0.03 | |

| (10 laps,30mm) | 1625nm | ≤0.5dB | ≤0.1 | |

| (1 lap,20mm) | 1550nm | ≤0.3dB | ≤0.1 | |

| (1 lap,20mm) | 1625nm | ≤1.0dB | ≤0.2 | |

| (1 lap,15mm) | 1550nm | – | ≤0.5 | |

| (1 lap,15mm) | 1625nm | – | ≤1.0 | |

| Mode field diameter | 1310nm | 8.8±0.4 | 8.6±0.4 | |

| Dimension parameter | Warp degrees | ≥4.0 | ≥4.0 | |

| Cladding diameter | 125 ± 0.7 | 125 ± 0.7 | ||

| Core/package concentricity | ≤0.5 | ≤0.5 | ||

| Cladding non-circularity | ≤1.0% | ≤1.0% | ||

| Coating diameter | 243± 5 | 243± 5 | ||

| Coating concentricity | ≤8 | ≤8 | ||

| Coating roundness | ≤3% | ≤3% | ||

| Mechanical property | Strain | ≥1.05% | ≥1.05% | |

| Tensile strength(10m) | 15% Weber fracture probability | 2.76 | 2.76 | |

| 50% Weber fracture probability | 3.45 | 3.45 | ||

| Fatigue parameters Nd | ≥ 22 | ≥ 22 | ||

| Coating peak stripping force N | 1.0~8.9 | 1.0~8.9 | ||

| Coating average stripping force N | 1.0~5.0 | 1.0~5.0 | ||

| Environmental

performance |

Additional damping temperature cycle (-60℃ ~ +85℃)

dB/km@1310nm,1550nm, 1625 nm |

≤ 0.05 | ≤ 0.05 | |

| Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm,

1550nm, 1625 nm |

≤ 0.05 | ≤ 0.05 | |

| High temperature aging(85±2℃,30 days ) dB/km @1310nm,1550

nm, 1625 nm |

≤ 0.05 | ≤ 0.05 | |

| Additional attenuation of flooding (23±2℃,30 days ) dB/km

@1310nm,1550nm, 1625 nm |

≤ 0.05 | ≤ 0.05 |